These convenient container-mounted configurations are the perfect solution when wall-mounted equipment is impractical.

Welcome to the Lafferty Learning Center

Discover new products and learn how to select, install, operate, and maintain chemical application equipment. The Lafferty Learning Center presents decades of institutional knowledge, tips/tricks, and best practices in a visual multimedia format.

Product specific guidelines are provided in the Installation and Operation Instructions for each unit, which are available on the main Lafferty website.

Post Archive

Maintenance Principles for Water-Driven Venturi Systems

This video tutorial reviews simple principles to maintain top performance of Lafferty applicators and dilution systems over time.

Low Water Pressure?

Learn how Lafferty venturi systems use water pressure to dilute chemical, and overcome low water pressure issues with a booster pump.

ASSE 1055 Certified Mixing Stations

Select Lafferty Mixing Stations are certified to meet ASSE 1055, which is a widely-recognized standard for chemical dilution devices with an integral method of backflow prevention. Operators and inspectors can be...

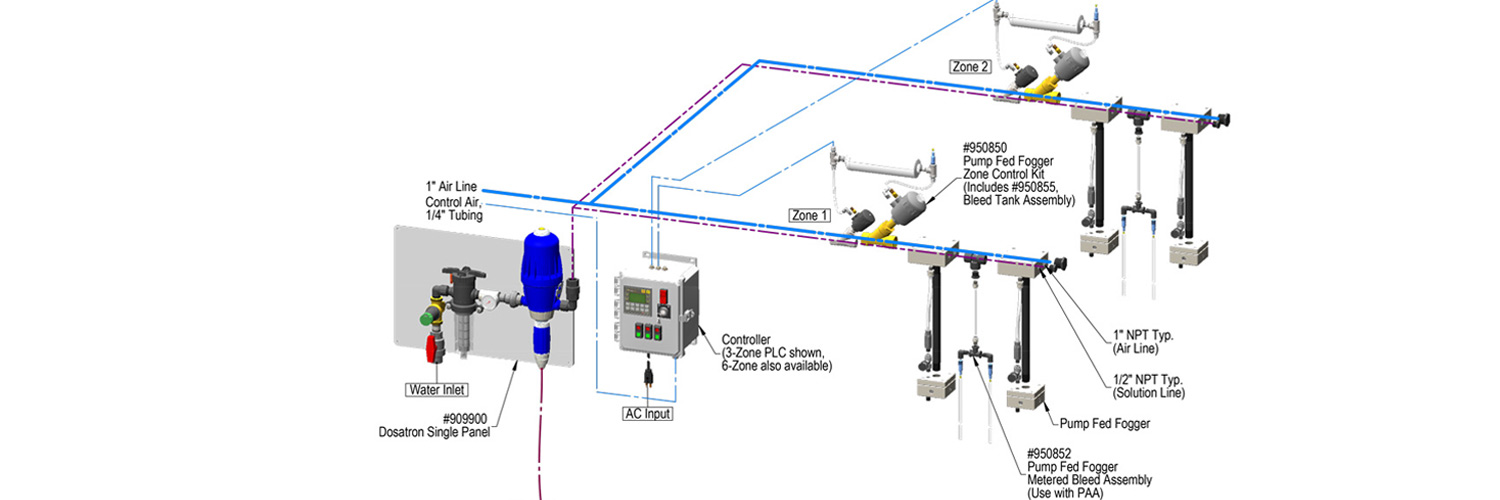

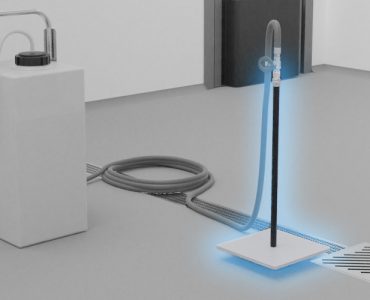

Pump Fed Foggers Overview & Installation

Pump Fed Foggers receive ready-to-use chemical solution from a Central Chemical Feed System. Air and chemical solution flow can be activated manually or activated in multiple zones using Vision Fogger Controllers.

Dilution Procedure for Water-Driven Venturi Systems

This video tutorial demonstrates how to dilute concentrated chemicals to the desired ratio using a Lafferty venturi applicator and metering tips.

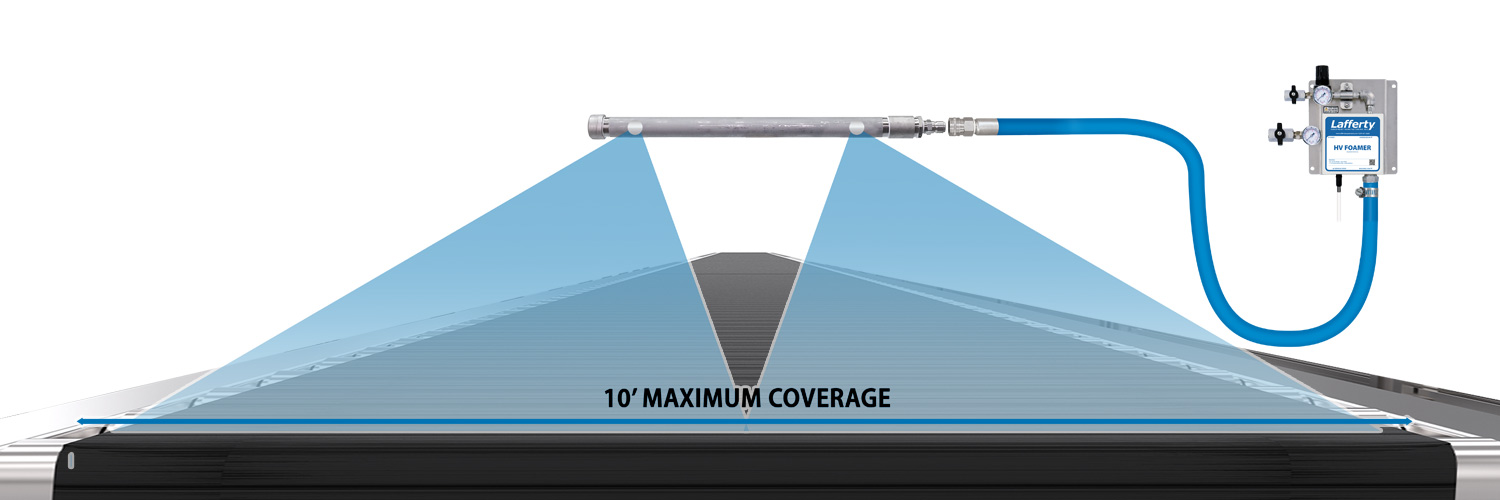

Foam Bars with Spreader Nozzles

Lafferty Foam Bars include machined stainless steel Spreader Nozzles, which rotate inward to overlap output for heavier foam coverage over a narrower area, and outward to maximize coverage width.