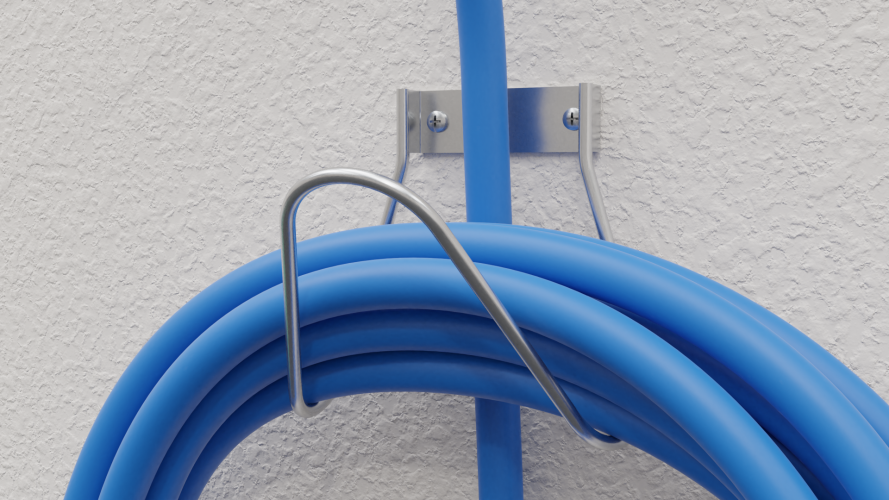

Learn how to properly install Lafferty stainless steel hose racks to ensure the longest possible service life for hoses and equipment.

Welcome to the Lafferty Learning Center

Discover new products and learn how to select, install, operate, and maintain chemical application equipment. The Lafferty Learning Center presents decades of institutional knowledge, tips/tricks, and best practices in a visual multimedia format.

Product specific guidelines are provided in the Installation and Operation Instructions for each unit, which are available on the main Lafferty website.

Post Archive

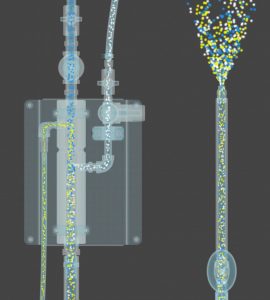

Metering Tip Installation and Removal of Broken Tip – Video

This short video demonstrates how to use the metering tip driver to carefully install a metering tip and how to remove a broken tip.

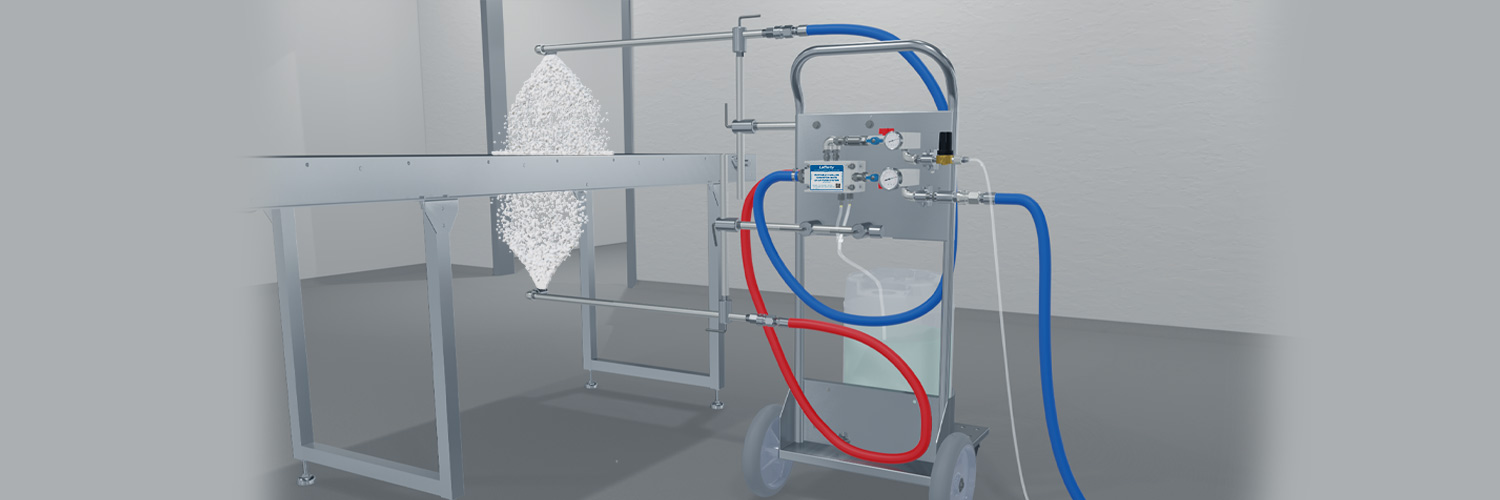

Multifunction Demonstration System

Apply chemical as liquid spray, airless foam, or air-assisted foam with this all-in-one demonstration system.

Pump-Up O-Ring Replacement Guide

Proactive preventative maintenance is important to ensure reliable performance.

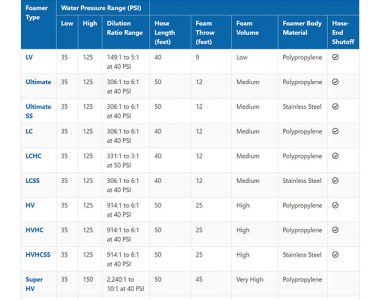

Foamer Demonstration Videos

Watch Lafferty Foamers in action to select the best model for the job based on the available utilities, desired foam throw distance, and most efficient coverage speed.

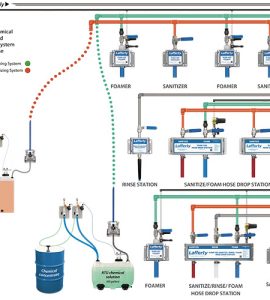

Hands-Free Mixing Stations

Foot-lever activation allows for sanitary, hands-free chemical mixing and dispensing.

Stainless Steel Foggers

Stainless steel materials of construction may be required for certain pharmaceutical or food/beverage manufacturing facilities. Many fogger models are available with stainless steel fogger bodies and metering tip...