Cleaning and sanitation is a critical part of the brewing process whether you’re a hobbyist, local Brewmaster, or the sanitation manager of a large beverage processing facility.

Lafferty chemical dilution and application equipment is built for demanding environments and constant use.

Article Contents

- Getting Started

- Compact Foamers and Sprayers

- Mixing Stations

- Moving On Up

- Uni-Body Airless Foamers

- Uni-Body Airless Foamers

- Uni-Body Sprayers

- Multifunction Uni-Body Systems

- Top of the Line

- Foamers

- Sanitizers

- Multifunction Hose Drop Stations

- Conveyor-Mate Systems

- Portable Systems

- Accessories

- Drum and Tote Sticks™

- Safe Flow Lids and Pail Sticks™

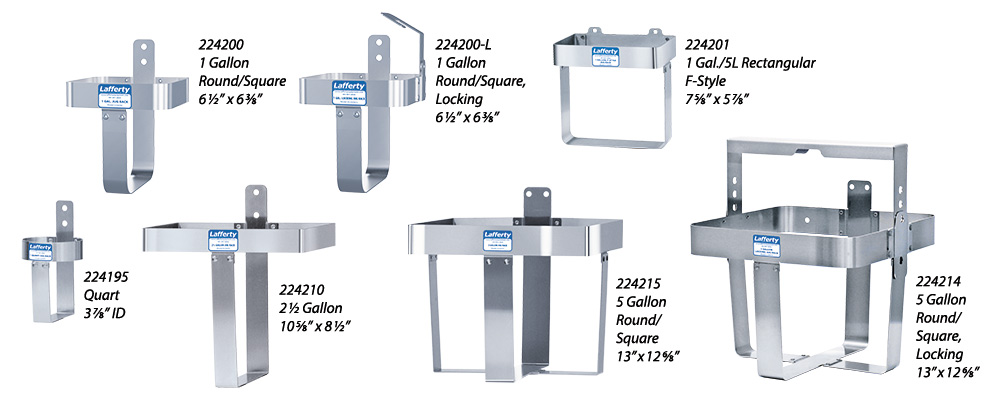

- Stainless Steel Hose and Jug Racks

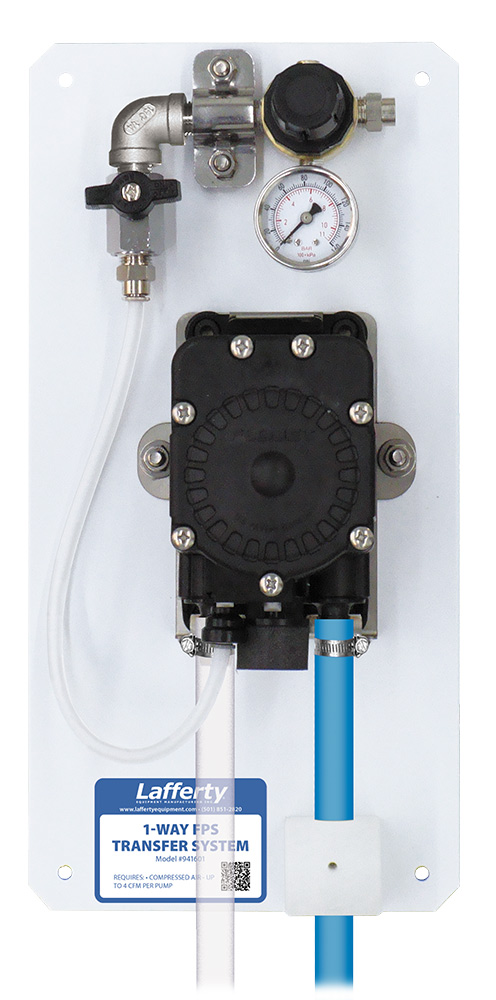

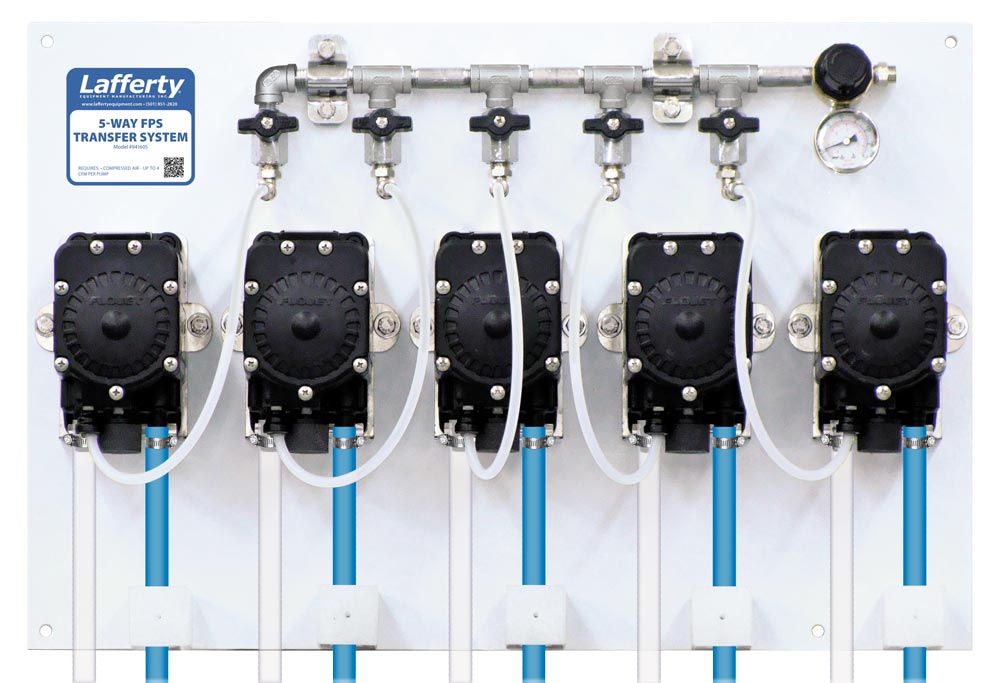

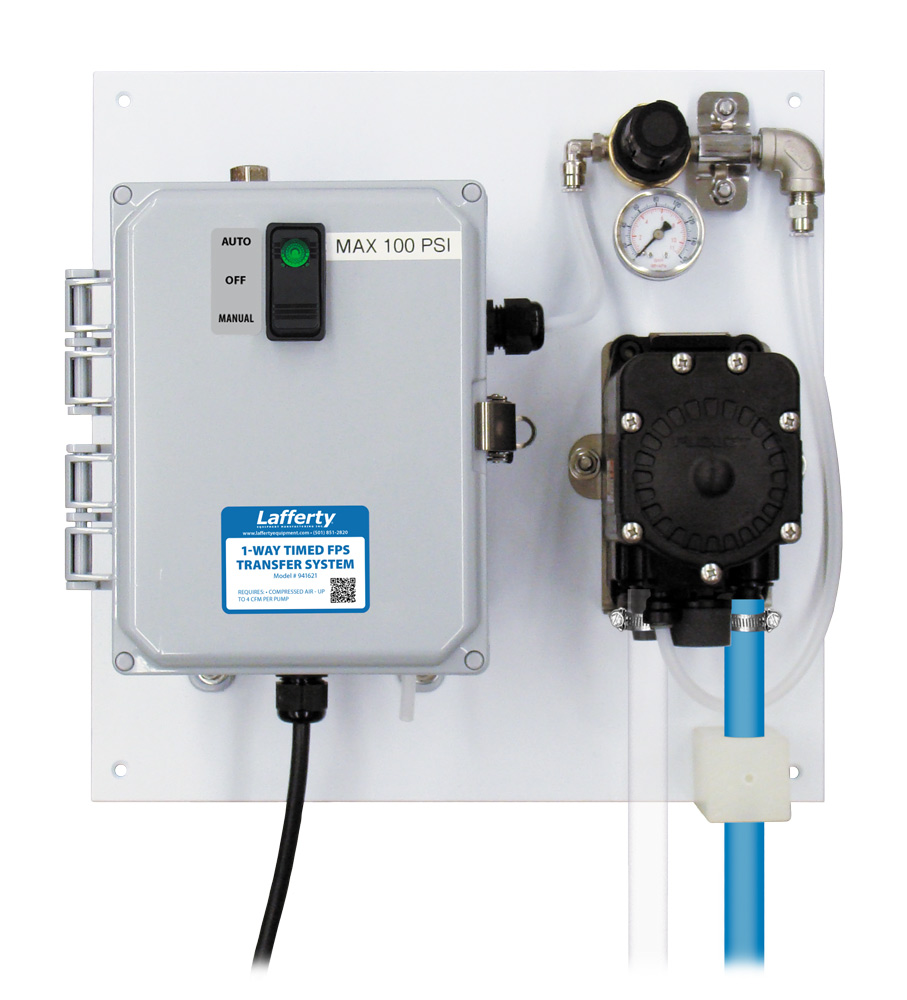

- Chemical Transfer Systems

This product guide is also relevant for wineries and distilleries!

NOTE: The equipment described on this page is WATER DRIVEN and dilutes chemical on demand using city water pressure. Lafferty also manufactures a wide range of AIR PUMP DRIVEN equipment that does not require water pressure (compressed air only), and equipment for boosted/high water pressure.

Getting Started

These basic models are easy for anyone to set up and use, but they aren’t just for beginners!

Compact Airless Foamers and Sprayers

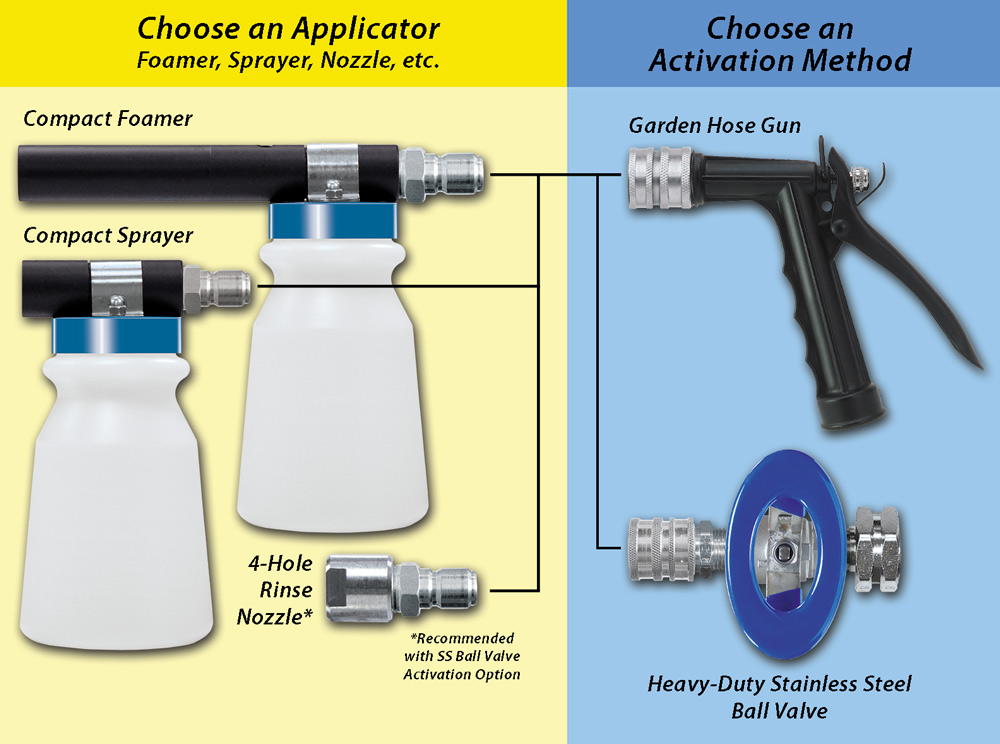

Install a metering tip based on the required dilution, fill the bottle with concentrated chemical, connect to city water pressure, and start cleaning.

Compact Airless Foamers create wet, clinging foam without compressed air. They are typically used with cleaning detergents/soaps.

#969925-B32 Model 25 Compact Airless Foamer is suitable for most situations, but Model 15 offers reduced output volume.

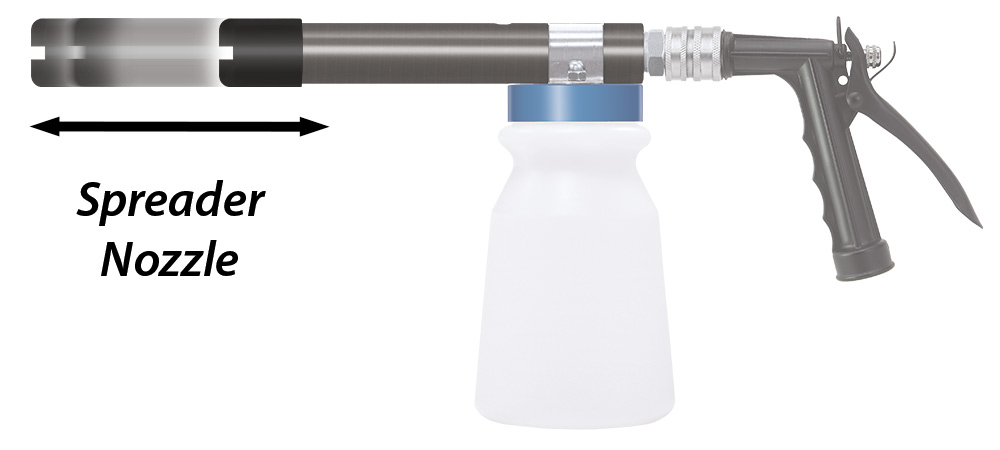

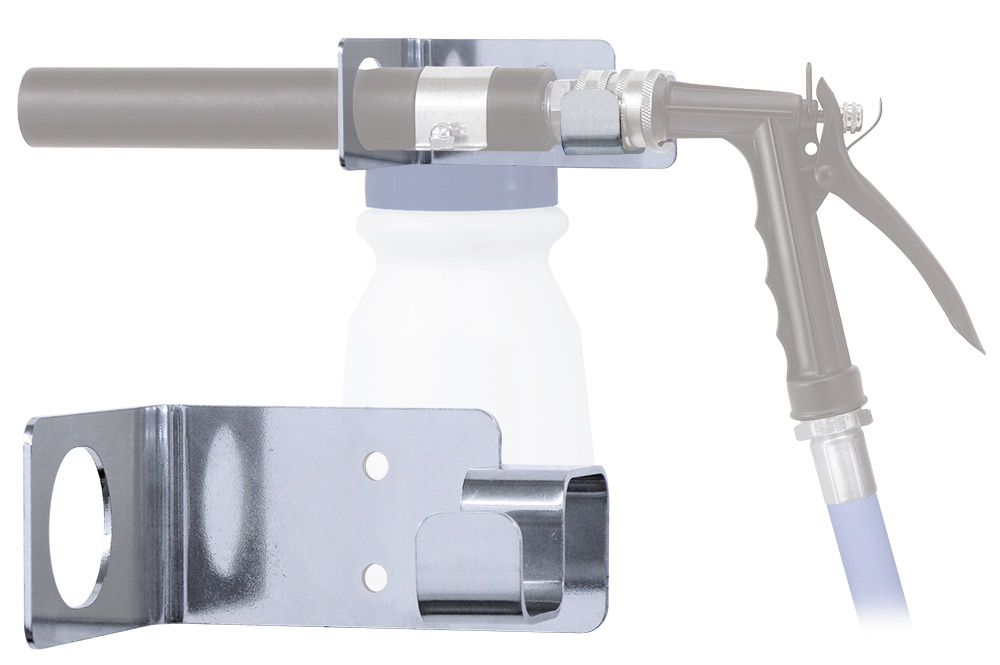

We recommend the Spreader Nozzle for close-range foaming and a Storage Rack to protect your investment.

Compact Sprayers project liquid spray and are typically used with sanitizing chemicals. The standard nozzle produces a 25 degree fan pattern, and alternate nozzles are available.

Choose a model based on the desired output volume. The low volume Model 20 has a flow rate of less than 1 GPM. Model 50 puts out a higher volume with a flow rate of 2.3 GPM @ 40 PSI.

One limitation of these sprayers is that the flow rate may not be high enough to achieve the super-lean ratios required for no-rinse sanitizers. See the “Sanitizers” section below for chemicals that require ratios weaker than 526:1.

Compact Foamers and Sprayers are available with a stainless steel ball valve for extra durability. The unique stainless steel 4-Hole Rinse Nozzle projects a powerful focused stream of water.

Mixing Stations

Mixing Stations dilute concentrated chemical on demand and fill any size container. We offer a factory-set choice of flow rate for each valve. The dilution ratio for each valve is set independently. Mixing Stations are available with 1-5 valves.

- Bottle Fill flow rate (0.62 GPM @ 40 PSI) to avoid splashing while filling small hand-held spray bottles.

- Low Flow (2.10 GPM @ 40 PSI) for mid-size containers (1-gallon jugs, Pump Up Foamers, etc.)

- High Flow (4.51 GPM @ 40 PSI) for filling larger containers such as mop buckets and air pump foamers.

Push Lever Mixing Stations require the user to hold a lever to dispense chemical to prevent overfilling.

Special High Volume Mixing Stations are suitable for quickly filling very large containers such as floor scrubbers or CIP tanks.

Refer to the metering tip chart in the instructions for each unit to confirm that it can achieve the required dilution ratio at your desired flow rate and available water pressure.

Moving on Up

Your business is growing and so are your sanitation and quality control processes. A permanent equipment setup makes it easier for employees to get the job done right.

Uni-Body Foamers and Sprayers

Consider installing wall-mounted units in areas that require frequent cleaning. Safety and ease-of-use are enhanced because the user doesn’t need to transfer chemical or carry it with them. Simply drop the suction tube into any size chemical container stored below the unit.

Lafferty “Uni-Body” Systems™ feature a durable, chemical-resistant, machined polypropylene body and are designed with cost-effectiveness in mind. The same type of systems are available with stainless steel mounting brackets or mounted on a portable stainless steel cart (see below “Top of the Line“).

Uni-Body Airless Foamers create wet, clinging foam without compressed air. They are typically used with cleaning detergents/soaps. Wet foam is ideal for rehydrating soil to facilitate removal.

#975075 Uni-Body A-25 Airless Foamer is suitable for most situations, but lower and higher volume units are available.

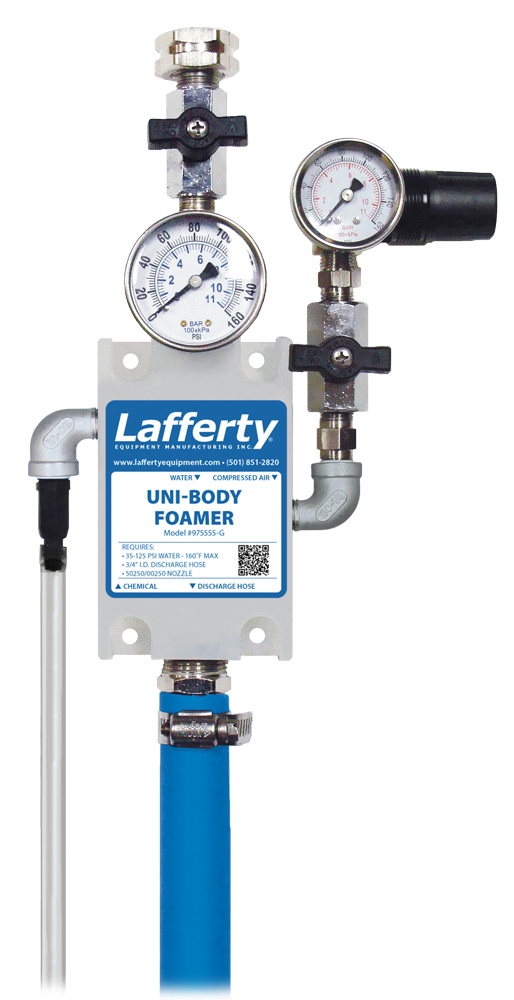

Uni-Body Compressed-Air-Assisted Foamers inject air into the chemical before it flows through the discharge hose to create rich, clinging foam.

Air-assisted foam clings better than airless foam and the foam consistency (wet/dry) is adjustable. Learn more about foaming with our Foam Cleaning Overview.

Choose a model based on the size of the objects and area being cleaned, available water pressure, and desired foam throw distance.

- #975545-G Uni-Body LV Foamer is suitable for smaller areas and objects. Conserve chemical and water!

- #975555-G Uni-Body LC Foamer is suitable for larger areas and faster coverage.

Uni-Body Spray-Alls project liquid spray. The standard nozzle produces a 25 degree fan pattern, and alternate nozzles are available.

Similar to the Compact Sprayers, above, choose a model based on the desired output volume (w-20, W-50, W-100).

One limitation of these sprayers is that they may not be able to achieve the super-lean ratios required for no-rinse sanitizers. See the “Sanitizers” section below.

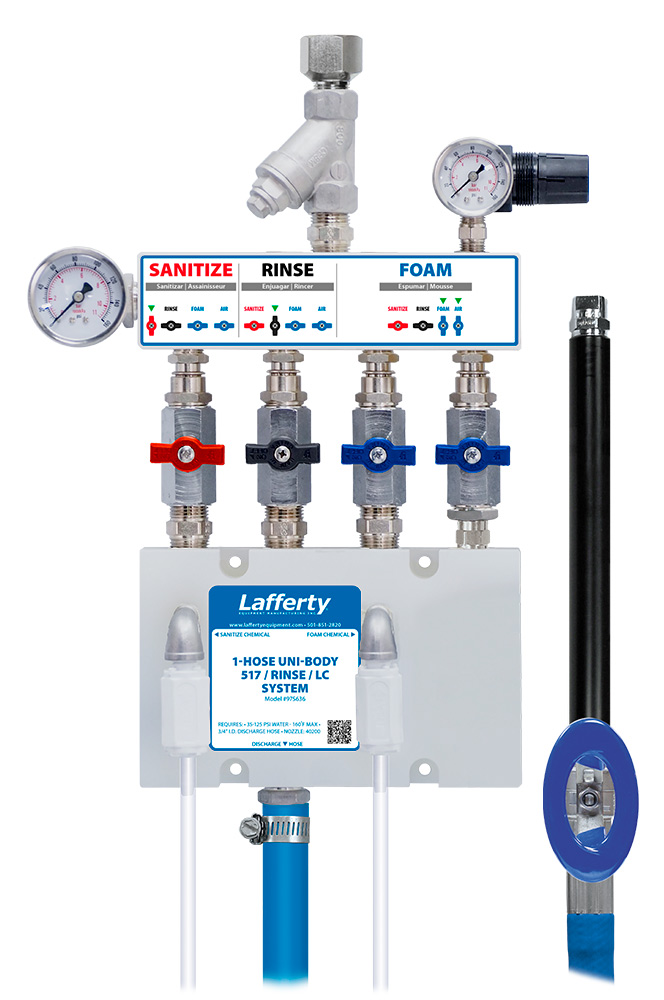

Multifunction Uni-Body Systems are available in many unique configurations to help you obtain the perfect combination of functions and flow rates.

Top of the Line

These industrial systems can be found in high-end food and beverage processing facilities around the world.

Foamers

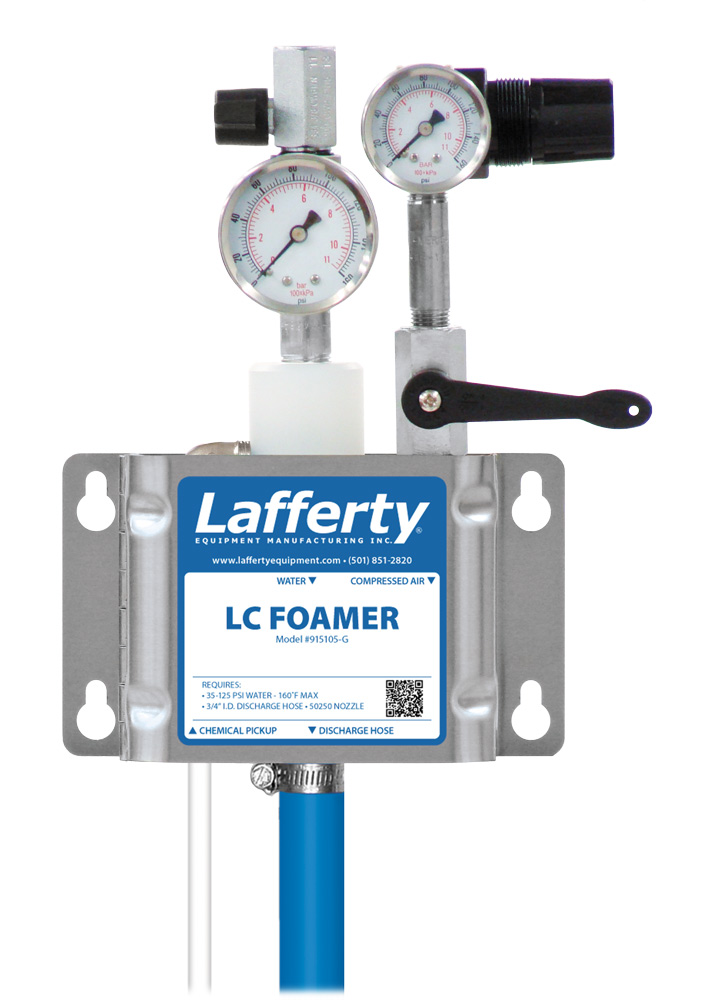

These Airless and Air-Assisted Foamers perform just like the Uni-Body series above, but with a few important distinctions.

- Stainless steel mounting brackets discourage abuse.

- Stainless steel ball valves provide superior chemical resistance and durability.

- Available with machined polypropylene or stainless steel bodies.

- Available with multiple chemical pickups for different chemicals or multiple dilution ratios of the same chemical.

- Standard Lafferty foamers are suitable for most caustic alkaline and acidic cleaning chemicals, but we manufacture acid-specific equipment for very strong/aggressive acids.

- Available with lock box (select units).

- High Volume Foamers produce an incredible amount of foam for quickly cleaning large areas. The Drum-Mounted HV Foamer (below) attaches directly to a drum of chemical concentrate.

- Choose a foamer based on the size of the objects and area being cleaned, available water pressure, and desired foam throw distance.

View our Foam System Comparison Chart and Foamer Video Demonstrations.

Sanitizers

Sanitizers are a special type of Sprayer. The flow rates are high enough to dilute ultra-concentrated, no-rinse sanitizers to the required lean ratios in a single step.

Choose a model based on the required dilution ratio (refer to dilution chart in the instructions for each unit) and the desired output volume.

2-Way models can dilute two different chemicals, or one chemical to two ratios.

Sanitizers options and upgrades are available to suit the chemicals being used. For example, Peracetic Acid (PAA) may require different check valve materials or a stainless steel body instead of polypropylene.

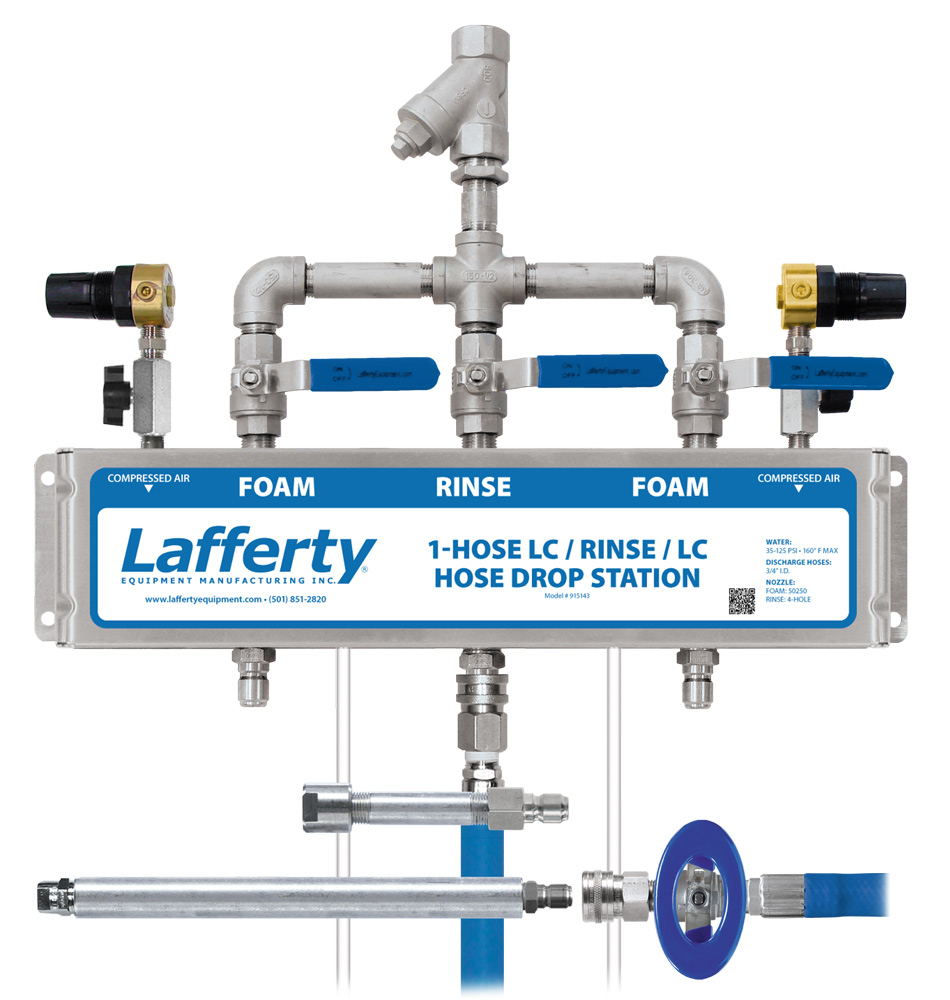

Multifunction Hose Drop Stations

Hose Drop Stations feature a stainless steel mounting bracket containing dedicated foamer/injector bodies for each function. Some models include quick disconnect hoses and nozzles for each function. Incompatible chemicals require a Hose Drop Station with dedicated hoses for each function.

Hose Drop Stations are available with a wide range of functions and flow rates. Most single function units can be combined into custom Hose Drop Stations – contact us for details.

Conveyor Cleaning Systems

Conveyor-Mate Foam and Sanitizer Systems apply clinging foam or liquid sanitizer to one or both sides of a moving conveyor belt for CIP cleaning. Unique stainless steel Spreader Nozzles project a wide pattern and can be adjusted to suit any orientation.

Some models include a quick disconnect foam arm for conveyor cleaning and a hand-held wand/nozzle for manual washdown.

Portable Systems

Portable configurations allow one system to service a larger area than hard-plumbed, wall-mounted systems. Portables are ideal for growing facilities where the layout is evolving and hose length requirements may change.

Most Lafferty units are available mounted to a stainless steel cart.

Chemical Handling Accessories

Chemical management made simpler, neater, cleaner and safer. Lafferty offers convenient accessories to complement our wide range of chemical dilution and application equipment.

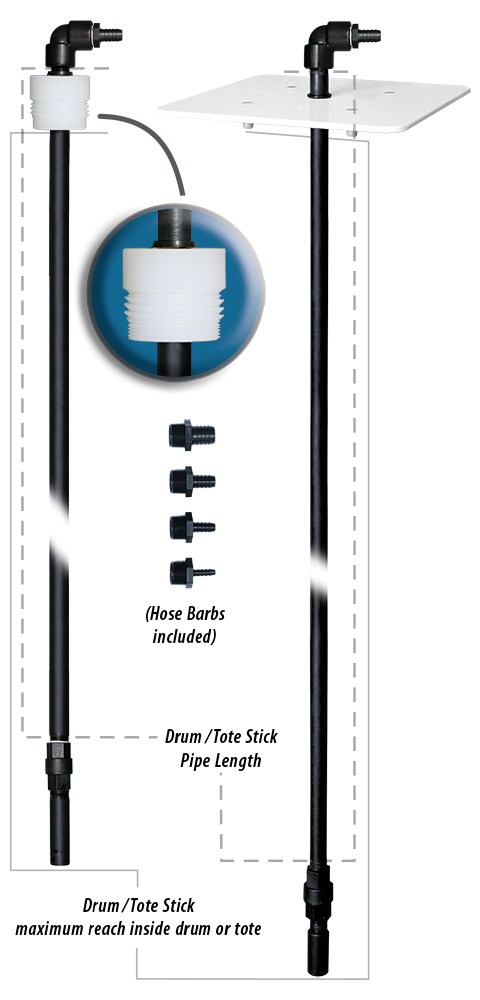

Lafferty Drum and Tote Sticks™

Drum and Tote Sticks™ facilitate dispensing from bulk containers. These chemical-resistant, polypropylene accessories include check valves and hose barbs to attach tubing of various sizes.

Lafferty Safe Flow Lids and Pail Sticks™

Safe Flow Dispensing Accessories™ are available in many configurations to fit different types of container openings and depths.

Hose Racks and Chemical Jug Racks

Stainless Steel Hose and Jug Racks are the perfect companion for any chemical dilution or application system. Be proactive to eliminate OSHA hazards by keeping hoses and chemical containers neat, tidy, and safely off the floor.

Transfer Systems

Transfer Systems safely and efficiently move chemical from bulk containers to secondary containers using an air-operated pump.

Contact Us

We’d love to hear about your challenges and goals so that we can recommend the best equipment for the job!

_Illustration.jpg)

.jpg)