What is Venturi Proportioning?

Venturi proportioning (also known as diluting or mixing) equipment uses water pressure to “draw” chemical concentrate into the water stream. This method of chemical dilution has many advantages.

- Low maintenance – no moving parts

- Easy to select, install, and operate

- Accurate and repeatable

- Field adjustable

- Safe – less chemical handling

- Cost effective

- Useful in countless environments

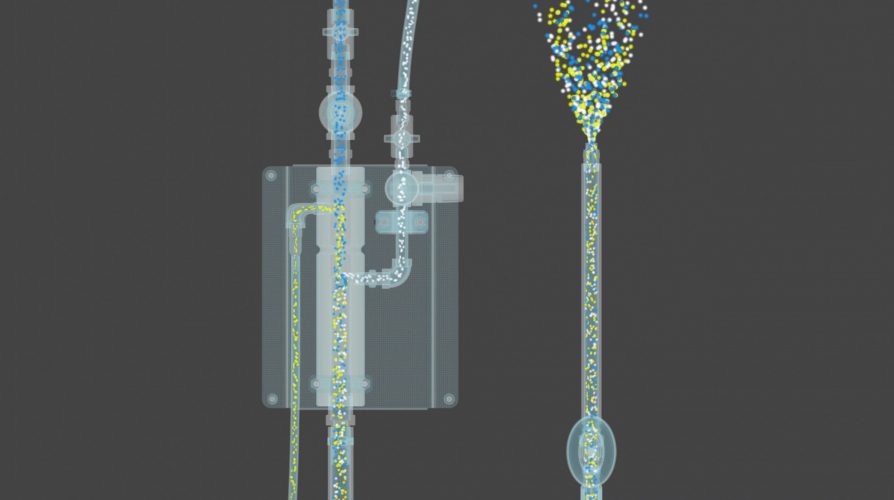

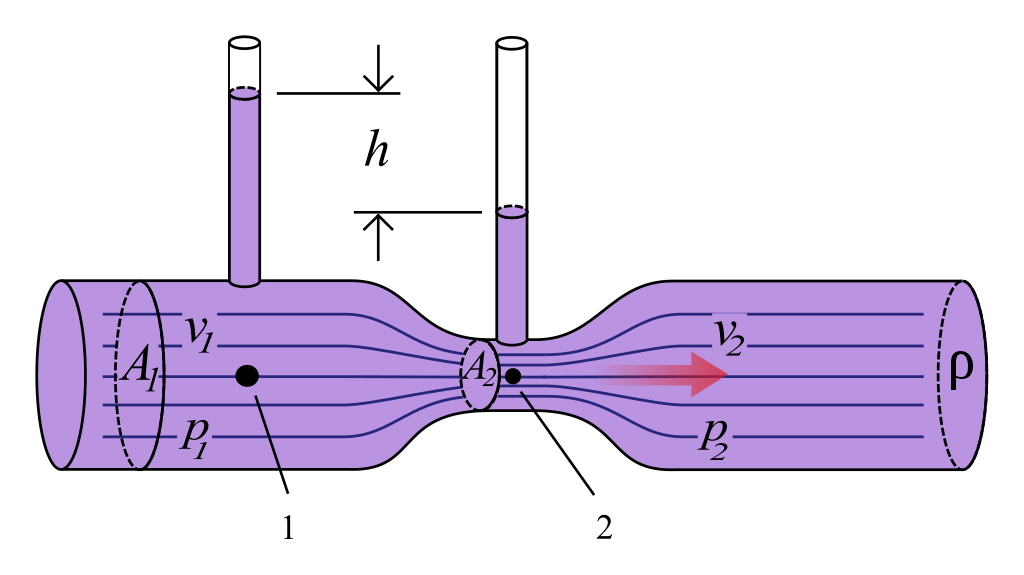

Venturi Theory Applied

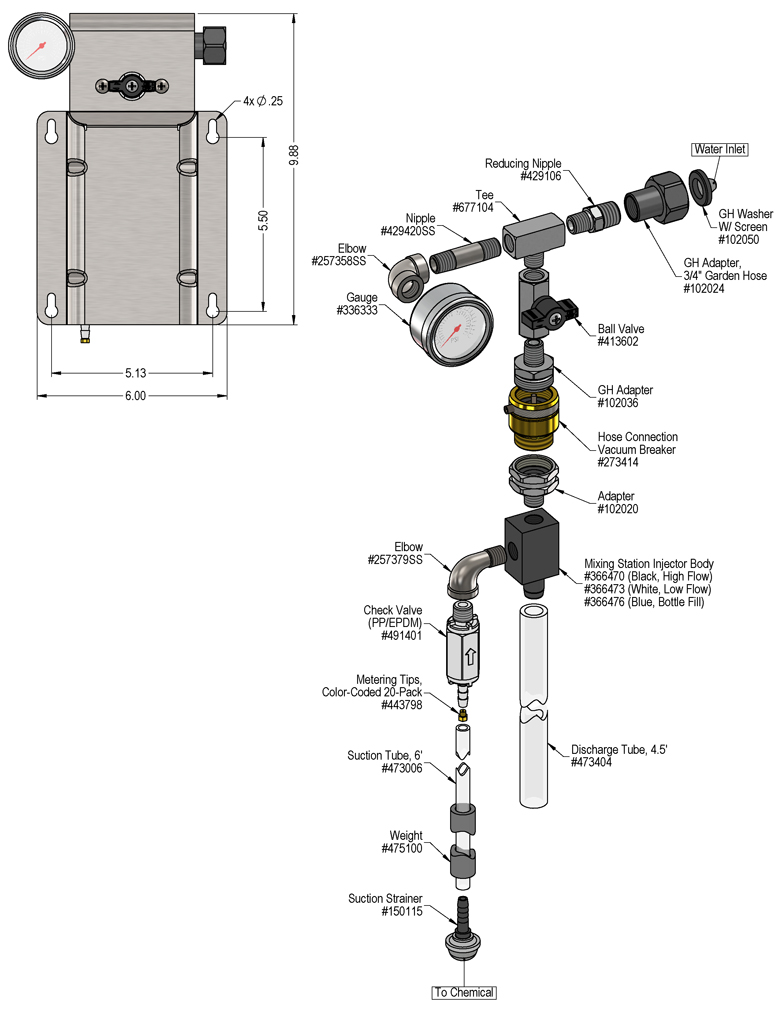

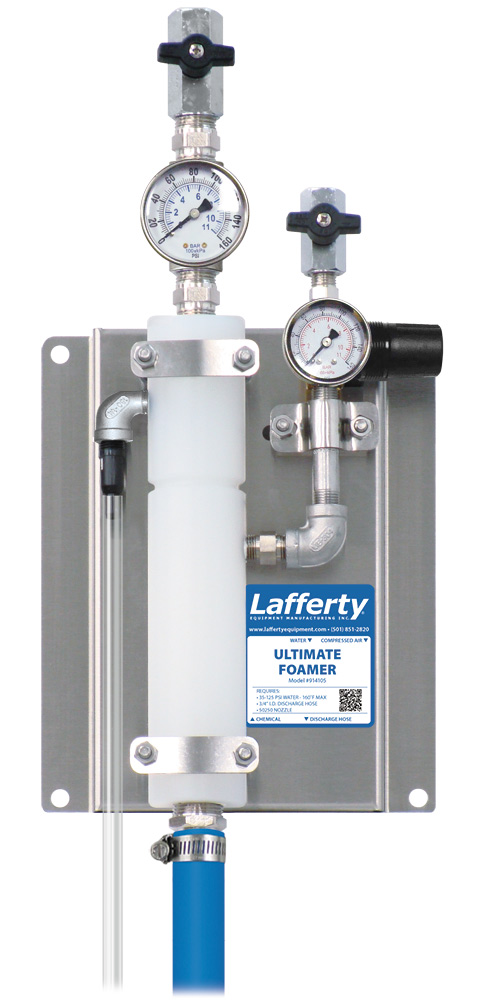

The heart of any venturi dilution system an injector or foamer “body”. Each type of body is designed to produce a different flow rate and accommodate different incoming water pressure ranges (city, boosted, or high).

The body inlet is connected to a water source and the chemical pick-up tube (AKA suction tube) is placed in the chemical concentrate. The body discharge accommodates an open-flow tube or hose with nozzle assembly (depending on the type of system).

When a venturi system is activated, water flows through the flow-restricting body and speeds up due to the decreased volume. This creates a vacuum in the body that is used to draw chemical concentrate into the water stream. Chemical and water mix in the body and as they flow through the discharge hose to the point of application or dispensing.

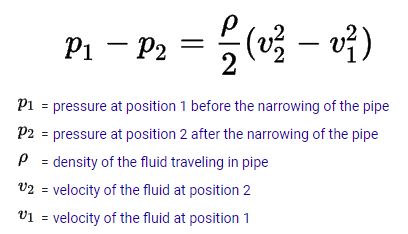

For a more scientific understanding, the venturi effect can be explained by Bernoulli’s equation. However, Lafferty provides online calculators – so don’t worry about the math!

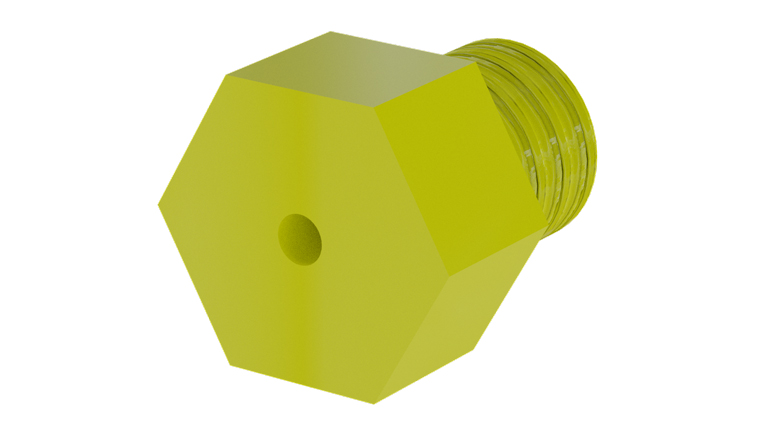

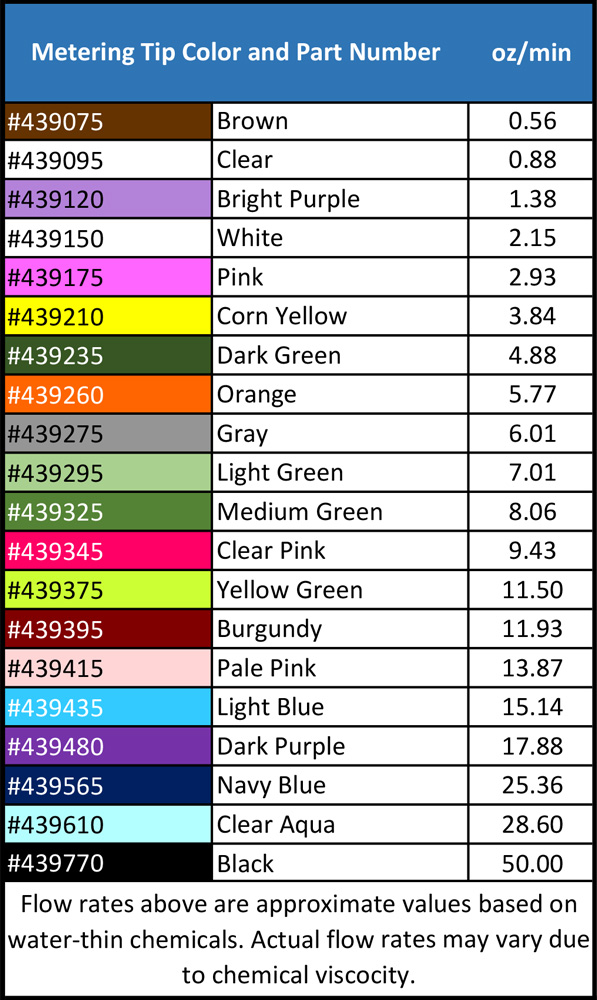

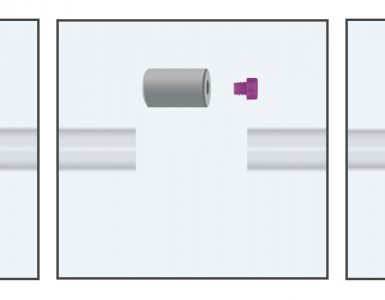

Metering Tips

Most venturi systems come with 20 color-coded precision metering tips. Use no metering tip to allow the maximum chemical draw into the water stream (no restriction). To set a weaker dilution and use less chemical, install a metering tip in the pick-up tube to restrict the flow of concentrated chemical. “Larger” tips allow chemical through at a faster rate and increase the strength of the final solution.

Be careful! Each tip color allows a fixed volume of chemical through at any time. However, the volume of water being mixed is proportional to the incoming water pressure. Because of this, fluctuations in the water pressure will cause variations in the final dilution ratio.

Higher-than-expected water pressure = higher water flow rate = weaker-than-expected dilutions.

Choose a metering tip based on the actual water pressure during operation.

What Does This Mean?

For facilities with stable, consistent water pressure:

No special action is required. Per standard installation and operation instructions, choose a metering tip based on the water pressure during operation. The Lafferty Metering Tip Calculator can assist.

A minor fluctuation in city water pressure of +/-5 PSI can result in a fluctuation of +/-6% in solution strength.

A water pressure gauge allows the operator to ensure that the incoming water has not changed significantly during operation. Many equipment configurations include water pressure gauges, and they are optional for other systems.

For facilities with widely varying water pressure or where minor dilution ratio variations are unacceptable:

First, consider if other types of equipment are better suited for situations with poor water utilities. Lafferty offers equipment to utilize prediluted chemical or boost water pressure with a pump, and many systems only require compressed air.

However, if water-driven venturi equipment is being used with questionable water utilities, a water pressure regulator may help. This is typically a consideration for facilities using city water pressure, which can vary greatly between 25 and 125 PSI.

If the incoming water pressure is over 40 PSI and cannot be adjusted, consider installing a fixed 40 PSI regulator on the water supply line. This will prevent pressure spikes and over dilution due to higher-than-expected water pressure.

With an adjustable pressure regulator, it is possible to “dial in” and achieve a specific dilution ratio. This is helpful in high-accuracy situations to achieve specific dilutions that may fall between metering tips sizes at normal facility water pressure. To see the effect of water pressure on dilutions, open the Lafferty Metering Tip Calculator and select a unit. Try entering different actual water pressure values until a metering tip shows the desired dilution ratio (make sure to stay within the pressure range of the water supply).

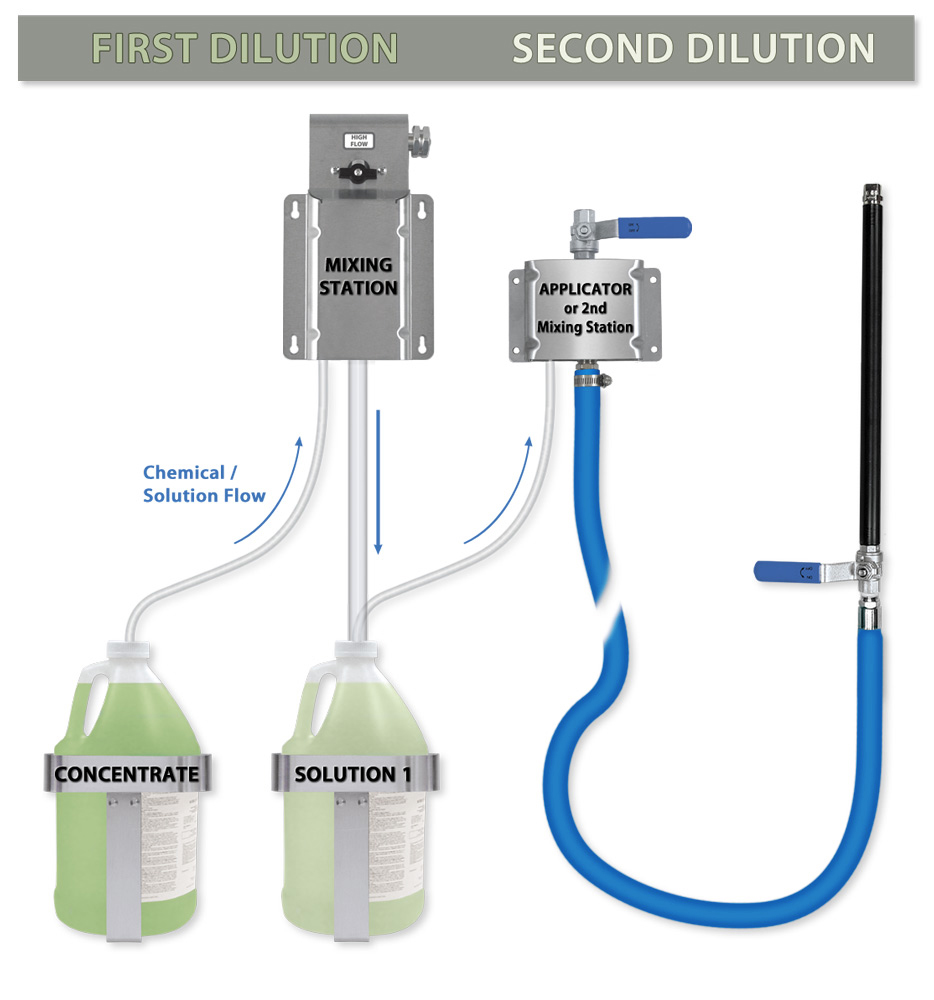

Double Dilution

Despite manufacturing hundreds of unique variants, we may not offer a unit that can achieve the desired flow rate AND dilution ratio range. This is because the dilution ratio range is fundamentally determined by the unit flow rate and available water pressure.

For example, if very low flow output is required at extremely lean (weak) dilutions, a low flow sprayer can’t provide enough water to dilute the chemical enough. Therefore, the original concentrated chemical will need to be diluted twice (see illustration).

Use the Lafferty Double Dilution Calculator for metering tip selection assistance.

Low Water Pressure Problems?

Yes! It is possible to boost low incoming water pressure into the acceptable range. View our guide to learn more.