These heavy-duty check valves are used in Lafferty pressure washer foamers and sprayers, boosted and high water pressure systems, or when stainless steel and maximum durability are required.

Check valves may become clogged with physical debris or chemical buildup. The Viton valve seat and spring may also need to be replaced due to chemical exposure.

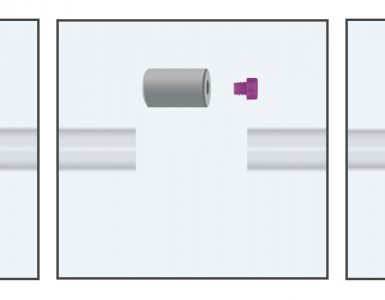

The spring, valve, and valve seat are held inside a threaded 2-part body that can be separated using a vice and/or pliers. Caution: internal components are spring-loaded.

| Part Number | Description with Link |

|---|---|

| 491325-V | Check Valve, Chemical, SS/V,1/4″ MPT x 1/4″ & 1/2″ Hose Barb |

| 491328 | Check Valve, Chemical, SS (Viton), 1/4″ FM |

| 491325-KIT | Repair Kit For 491325-V, 491328 Check Valves |

Check Valve 491325-V Disassembly Video

Service Tip – “Lack of Suction”

Consider this technique to troubleshoot lack of chemical injector suction, since the root cause could be related to the check valve or a blockage in the injector.

With the check valve removed from the injector body, the injector should draw air (create suction) during operation. If this is true, the check valve is likely causing the lack of chemical suction. Clean or replace the check valve as described above.

If water discharges from the injector suction port during operation (no suction), look for debris that may be obstructing the injector body suction orifice. Do NOT drill out or modify the injector orifices – there are no user-serviceable parts inside the injector.

Descale the injector if there is no obvious physical blockage. Scale buildup can reduce the flow rate of the injector over time, which eventually leads to a lack of suction. Water quality and chemical composition play a role in whether or not scale buildup will require frequent mitigation.

Refer to our Venturi Maintenance Video or unit-specific troubleshooting guides for details.