The Lafferty Sentry™ features a stainless steel mechanical pump that is field-tested over 1 million strokes. This post explains possible performance issues that can be rectified by simple cleaning or part replacement.

Contents

- Clogged Nozzle Cleaning Walkthrough – Read this first

- Diagrams

- Troubleshooting Guide

- Priming Instructions

- Preventive Maintenance

- Piston O-Ring Replacement

- Pump Head Replacement

- Upgrading from Previous Design

- Contact Us

The appearance of the spray output depends on many factors. Gel vs. liquid product, adjustment bolt setting, force and speed of pedal press, etc.

An uneven spray pattern does not indicate improper performance or diminish the amount of product being dispensed.

Clogged Nozzle Cleaning Walkthrough

Situation and Problem:

The Sentry at the main entrance to an office building is used many times per day to dispense hand sanitizer gel.

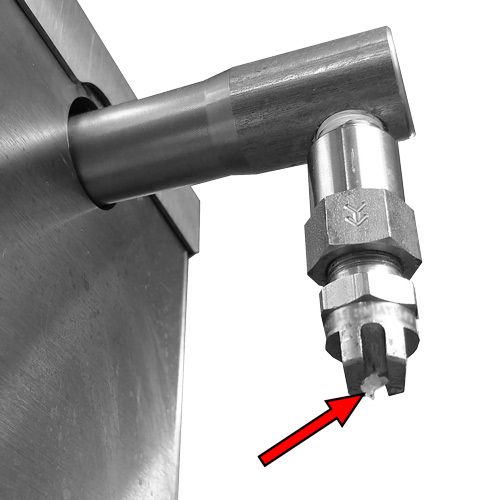

The appearance of the spray output is sometimes inconsistent – most notably on Monday mornings. Sticky residue/buildup is visible on the outside of the nozzle.

Solution:

First, wipe residue from the nozzle exterior with a cloth or brush.

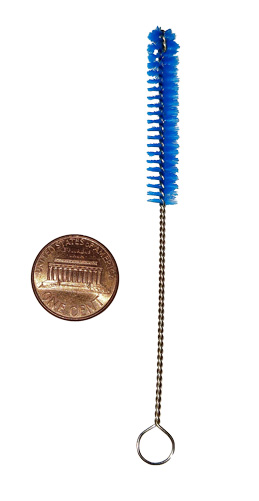

Gel products are more likely to experience this issue than liquids. Pipe cleaners and stiff bristle brushes are excellent tools to clear the tiny nozzle opening and exterior grooves.

If the problem persists, clean inside the nozzle.

It is likely that the same chemical buildup seen on the outside of the nozzle is also present inside.

Without removing the nozzle from the Sentry, insert small brush or pin into the nozzle opening and move it around to dislodge dried chemical. When finished, firmly press the foot pedal 2-3 times to clear the nozzle. This procedure will clear most nozzle blockages.

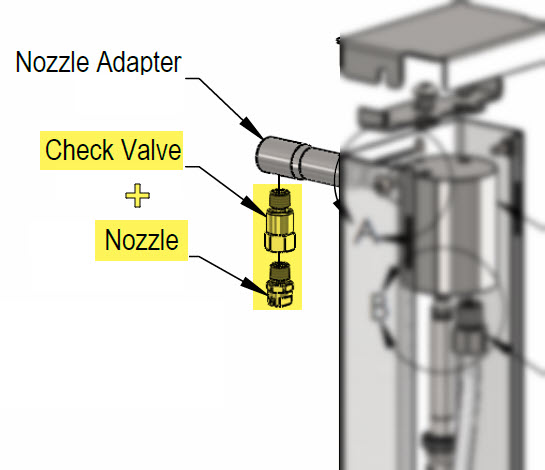

If the problem persists, remove the nozzle (and perhaps the check valve) for inspection and further cleaning.

Unscrew the nozzle from the check valve using a wrench. Press the foot pedal without the nozzle installed.

If product is dispensed: The pump, suction assembly, and discharge check valve are working correctly and the issue is simply nozzle blockage. Thoroughly clean and reinstall the nozzle.

If there is no output from the check valve: Remove the check valve from the nozzle adapter. Try hitting it with a blast of compressed air. This may dislodge the internal seals and resolve the issue. Soak it in warm water and wash away chemical buildup that may be causing the valve to stick in the open or closed position.

Most performance concerns can be resolved by cleaning the nozzle and check valve.

DO NOT remove the nozzle adapter from the pump body without consulting Lafferty.

The Sentry is ideal for high-traffic locations and daily use. Sanitizer product (particularly gels) may harden or congeal inside the nozzle and check valve with infrequent use.

Consider using a different chemical product if your unit requires frequent service. Contact us if your chemical is incompatible with the EPDM check valve seal material.

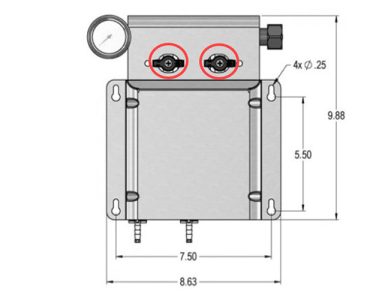

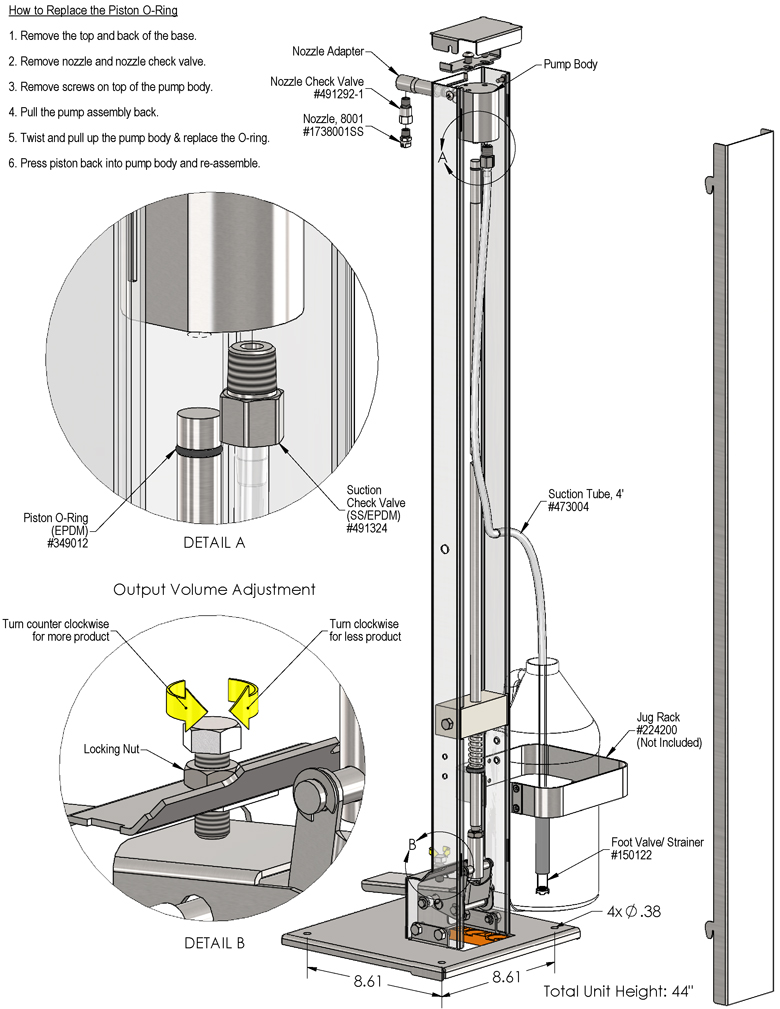

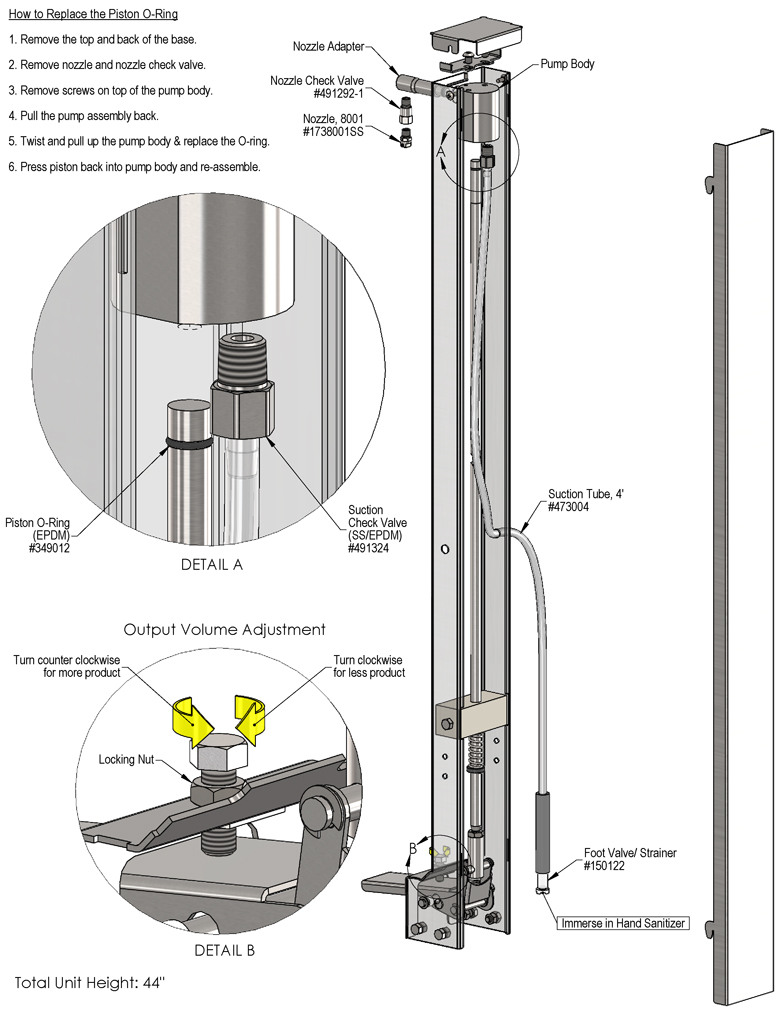

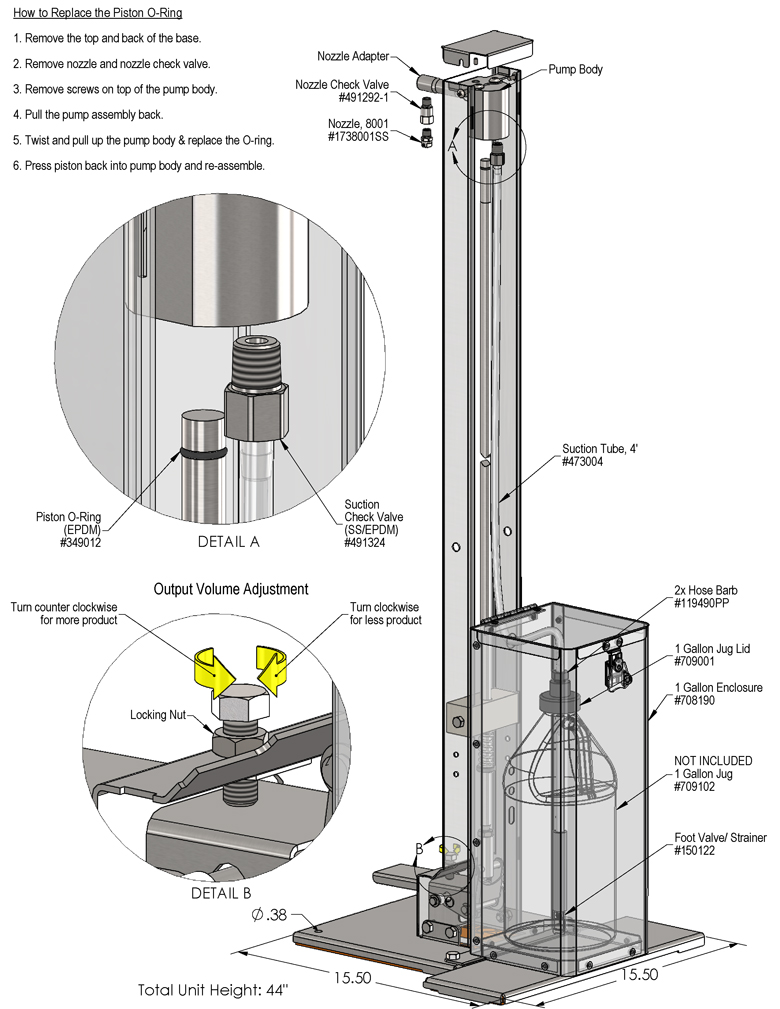

Diagrams

Click image to see full size diagram.

Sentry (Floor-Mount)

Sentry (Wall-Mount)

Sentry Secure

Troubleshooting Guide

- Keep in mind that the rugged design of this equipment necessitates very few serviceable components. Most performance issues can be resolved without disassembly, as described in the walkthrough above.

- Refer to the part diagram for your unit to understand the name and location of each serviceable component.

- BE CAREFUL when disassembling and reassembling components. Ensure that all connections are secure when finished.

- If you have any questions, please contact us before attempting service.

Consider the characteristics of the chemical being used, frequency of use, and installation location when troubleshooting Sentry performance.

This troubleshooting guide is adapted from the Installation & Operation Instructions that are available on the product detail page for each Sentry model.

| Problem | Possible Causes |

|---|---|

| Will not draw product or spray | 1, 2, 6, 7, 8, 9, 10 |

| Dispensing too little | 3, 5, 7, 9 |

| Dispensing too much | 4, 5 |

| Dispenses inconsistent amount and/or uneven output | 5, 9 |

- The unit needs to be primed.

- Prime the unit by repeatedly stepping on the foot pedal until it begins to spray. Initial priming takes approximately 25 strokes, but varies based on the viscosity of the sanitizing solution.

- Ensure that tubing connections are tight. See #8, below.

- If the output volume adjustment knob is set to dispense very little product, loosen the adjustment bolt (#3, below) to increase the flow while priming.

- Chemical tube not immersed in sanitizer solution or sanitizer depleted.

- Fully immerse tube or replenish.

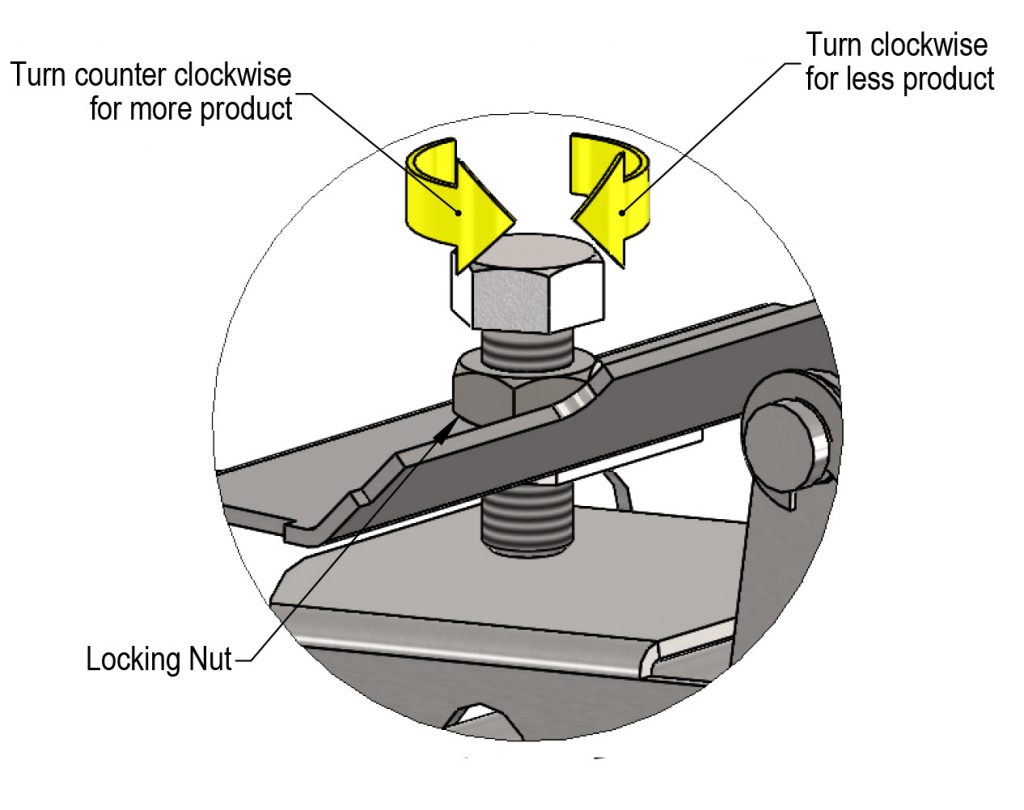

- Need to increase output volume.

- Loosen locking nut, turn adjustment bolt counter-clockwise, tighten locking nut.

- Need to decrease output volume.

- Loosen locking nut, turn adjustment bolt clockwise, tighten locking nut.

- Locking nut loose

- Check locking nut. Tighten if loose.

- Suction check valve stuck or failed.

- Clean or replace.

- NOTE: The suction check valve is only accessible with the Sentry backplate removed. It is NOT the same as the check valve in the nozzle assembly. See parts diagram.

- Foot valve / strainer partially blocked or suction tube kinked.

- Clean or replace foot valve / strainer.

- Straighten tubing.

- The chemical tube is loose, stretched out, or contains a pin hole or cut (sucking in air).

- Ensure that suction tubing connections are secure.

- Remove tube from hose barb, and cut off 1/2″ of tube. The freshly cut end will fit better than an old, loose tube.

- Reattach tube to hose barb or replace entire tube.

- Chemical build-up may have formed or dried out in the nozzle and/or nozzle check valve.

- Without removing the nozzle from the Sentry, insert small brush or pin into nozzle to remove dried chemical. Press pedal firmly to blow out. This will resolve most simple blockages.

- If necessary, remove and thoroughly clean the nozzle and nozzle check valve.

- To flush the entire fluid path, place the suction tube in warm water. Operate the foot pedal until water flows out of the nozzle for several seconds. See #1, above.

- NOTE: Nozzle blockage is more likely to occur with gel products.

- Piston o-ring may have worn after prolonged use.

- The piston moves up and down inside the pump body to create suction. This component should not be a troubleshooting consideration for newer units.

- Replace o-ring as needed. See diagram and piston o-ring replacement guide, below.

- CAUTION: Be careful to avoid pinching (and damaging) the 0-ring when re-installing the piston into the pump body.

Piston O-Ring Replacement

Refer to troubleshooting step 10, above.

There are 4 stages:

- Remove nozzle assembly

- Remove pump assembly

- Replace o-ring

- Reassemble unit

Pump Head Replacement

NOTE: Please consider ALL troubleshooting and preventive maintenance steps before replacing the pump head.

The Lafferty Sentry is built to last, and these parts may not ever need to be replaced under normal operating conditions.

The Piston O-Ring Replacement video above provides additional detail about the disassembly process.

- Sentry Pump Head Replacement Kit

- Part # 976900-KIT

Preventive Maintenance

Observe these procedures if the unit will be out of service for an extended period of time.

- Remove the suction tube from chemical and place it in warm water.

- Operate the foot pedal until water flows out of the nozzle for several seconds.

- Remove the suction tube from water and operate foot pedal until the nozzle stops spraying.

- The unit is now prepared for storage.

Older Unit?

Are you servicing a Sentry that was built prior to mid-2020? Previous designs included a small check valve inside the nozzle. The Sentry now includes a stainless steel check valve between the nozzle and nozzle adapter.

Updating your unit is easy! You’ll only require a new nozzle check valve.